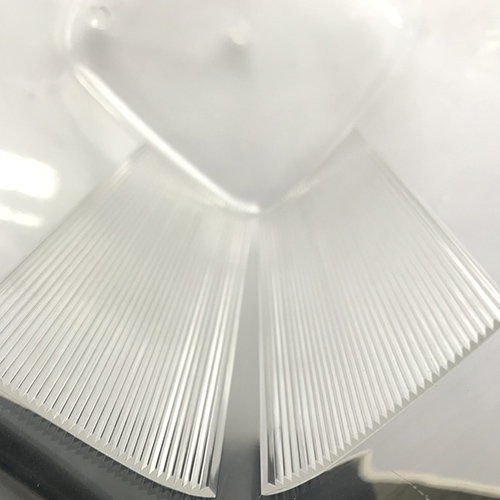

Plastic injection

Plastic Injection and reaction moulding of both commodity and high specification components for a variety of industry sectors worldwide.

ABS, PVC, POM, HDPE, LDPE.

PP, PS, HIPS, PC, TPU.

Other thermoplastic elastomeres.

Rigid Integral skin

Soft open cell

Polyester

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing Injection moulding uses a ram or screw-type plunger to force molten plastic material ... Injection moulding consists of the high pressure injection of the raw material into a mould, which shapes the polymer into the desired form.

Plastic injection molding is a common process used to make plastic components which are used by various industries.

It is a speedy production process, which permits the production of high quantities of the same plastic product in a short time frame.

The high-performance qualities of plastic materials able to resist at high temperatures are replacing the metals which are traditionally used in the production of plastics.

Plastic injection molding is a well-used process in the production of plastic components for the medical, aerospace, automobile and toy industries.

How does plastic injection molding actual work?

Plastic (either in pellet or gain form) is molten within the machine used for the injection molding and is then injected into the mould under high pressure.