What followed next was a redesign of the entire casting process to make what would otherwise be impossible possible. Within a few days of receiving the inquiry, P&Q were able to show LUG a workable solution where no one else could. In addition to the casting challenges, this product, and the environment. LUG has been able to grasp hold of these and run with them through innovative post-processing solutions, from high tolerance CNC machining through to the

customer-specific coating process and product-specific, grouped packaging.

P&Q years in lighting casting parts manufacturing, experienced engineers could solve different questions during manufacturing. P&Q accuracy is not the highest, but it is the most suitable for lighting fixture products.

| Product: | ||||

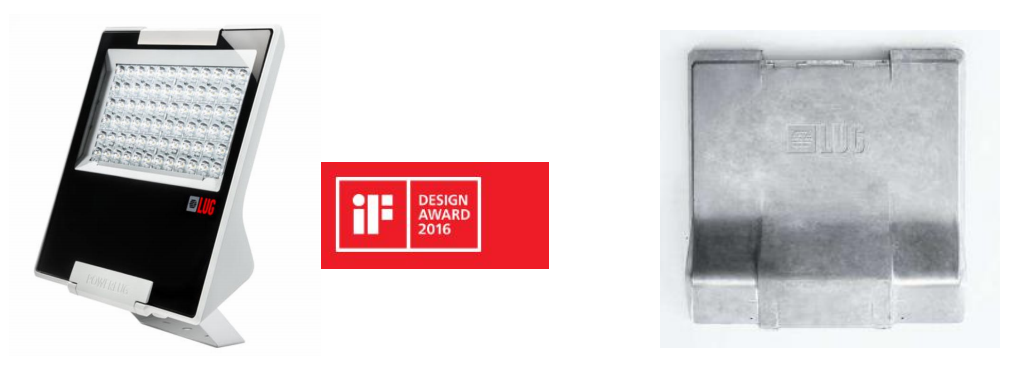

| Aluminium casting High Power LED Luminaire Flood Light- An indoor/outdoor Luminaire for industrial applications in the harshest environments | ||||

| Product Statistics: | ||||

| 403mm x 405mm x 95mm3.56 Kg Cast weightDA401 & LM9 Composite Alloy RoHS Compliant | ||||

| Processes: | ||||

| Die-cast and trim overflow CNC MachinePre-TreatCustomer Specific Coating process Pack and export as assembled unit. | ||||

| Project Overview: | ||||

| Initial enquiry receivedDesigns and drawings completed Tooling commissionedTooling approved and tested

Product testing and sign off completed Process designed and documentation created Ongoing supply |

||||

| Technical Challenges: | ||||

| Thermal control within the die-casting process / tooling Overall size/weight of product | ||||

Post time: Dec-14-2020